Guide to Fire Detection Technologies for Autonomous Robotic Fire Suppression Systems (ARFSS)

© Copyright 2023, Unifire AB. All Rights Reserved.

Selecting the right fire detection technology for your needs can be critically important to save lives and property.

FlameRanger, the world’s most advanced autonomous robotic fire suppression system (ARFSS), can work with them all.

This guide discusses Unifire’s review of the various fire detection technologies and their pro’s and con’s.

Introduction

With so many fire detection technologies on the market, it can be a bit daunting to determine the right detector, or combination of detectors, for your needs.

Here, we present and compare our thoughts and opinions about the most common detection technologies on the market that can be used for autonomous fire fighting systems, like Unifire’s FlameRanger™ and FlameRanger XT™.

The aim of this article is to provide general information and considerations when selecting the right detection technology for your needs. Of course, each customer must use his own judgement and ensure that his choice is approved in the local jurisdiction and by a licensed fire safety engineer. We hope this helps convey a sense of the pro’s and con’s to consider and discuss with a fire consulting engineer. Only a licensed fire consulting engineer is properly qualified to determine the best technology for your needs, and the opinions expressed herein are only intended to provide general information and should not be considered advice for any particular application.

IR3 Flame Detectors

How IR3 Flame Detectors Work

Flame Detectors detect actual visible flames within their field of view by using a variety of methods that analyze the light emitted in various wavelengths from a flame. The most reliable of flame detectors are called Triple-IR (abbreviated IR3 or 3IR). IR3 detectors have three separate detectors, each of which detects a different wavelength of light, and the detector analyzes and compares them and their ratios to better rule out false alarms.

Learn more about flame detectors at: https://en.wikipedia.org/wiki/Flame_detector

Advantages of Flame Detectors

For the majority of applications—but not all—IR3 flame are our top pick technology for autonomous robotic fire suppression systems. IR3 detectors are a well established technology, which are reliable & very fast acting. Because the are so fast and reliable and only react to the tell-tale wavelengths of fire, they have a very low susceptibility to false alarms. This extremely important feature makes IR3 flame detectors a very reliable detection technology for detecting actual fires the moment they break out.

Several IR3 flame detectors on the market are able to provide the fire’s coordinates. This provides a huge advantage for autonomous systems because the fire’s position can be accurately targeted and tracked. This can be done in a couple of ways:

- 2D “Vector Aiming: With a single detector by using a “vector” aiming, in which the robotic nozzle and the detector are placed close together and the robotic nozzle is then able to aim at the fire. These systems are two-dimensional, meaning that the system does not know the distance of the fire, but only its direction. But because the detector and the robotic nozzle are placed together, the distance plays little role. Moreover, these systems can compensate for the unknown distance of the fire by slightly increasing the vertical oscillation angle to ensure that the fire is suppressed at an around its source.

- 3D Dynamic Aiming: Even more impressive is the ability to determine the fire’s three-dimensional (3D) coordinates by triangulating the two-dimensional coordinates from two detectors. We call these systems “3D dynamic” autonomous robotic fire suppression systems because they locate and track the fire’s position in real time and in three dimensions and adjust to the fire as it moves, spreads or is diminished.

Moreover, although most IR3 detectors cannot provide the fire’s coordinates, they can still be used in autonomous robotic fire suppression systems like the FlameRanger. By placing these detectors locally in zones, each detector’s location is known by the system and if a fire is detected, the autonomous system responds with a pre-recorded spray sequence to suppress the area, or “zone”, in which the fire was detected.

Disadvantages of IR3 Flame Detectors

The disadvantages of IR3 are minimal. However, they are limited to detecting actual flames within their view. If a flame is not within the detector’s view, the system will not react.

Moreover, IR3 flame detectors do not react to a heat build-up. This is both an advantage, but can be a disadvantage when compared with thermal imaging cameras, which can detect a heat buildup even before a fire breaks out. As described below, however, the advantage of early detection from a thermal imaging camera is off-set by its susceptibility to false alarms from benign heat sources. For this reason, we still often prefer IR3 flame detectors over thermal imaging cameras, particularly in scenarios where external benign heat sources may cause a false alarm, such as where there may be moving vehicles.

Conclusions About Flame Detectors

IR3 flame detectors are generally a very fast and reliable way to detect a fire as soon as it breaks out in the detector’s view. They are highly resistant to false alarms, and they are not triggered by smoke or hot objects, which can be either an advantage or a disadvantage, depending on your risk and requirements.

Thermal Imaging Cameras

How Thermal Imaging Cameras Work

Thermal imaging camera systems detect heat in the infrared wavelengths. They can accurately read the temperatures of all surfaces within their field of view. The cameras themselves are typically connected to a computer that reads the data from the camera and displays it on a video monitor. Software allows the user to set numerous parameters, including pre-alarms at any desired temperature or change in temperature in a certain amount of time, alarms in certain areas (zones) of the field of view, and to ignore areas that are known to have hot objects you don’t want triggering an alarm.

Learn more about thermal imaging at: https://en.wikipedia.org/wiki/Thermal_imaging_camera

Advantages of Thermal Imaging Cameras

Quality thermal imaging camera systems are very good at providing early detection of a possible fire, even before it has broken out or before it is visible as flame (such as when it is smoldering under the surface). They typically react very quickly and with fairly high resolution.

Their ability to give an early warning is one of the primary advantage of thermal imaging cameras. They are very flexible in their ability to set alarms to the customer’s needs and site conditions. They also allow a human operator to see on a video monitor the heat of objects in the room, making it very easy and intuitive to see potential problems as they develop, and also to signal trouble quickly as it develops.

Another advantage of thermal imaging cameras is that they are able to provide location information of the heat source. This information can be used by an autonomous robotic fire suppression system in order to guide a robotic nozzle to suppress the fire or heat buildup.

It is important to point out that thermal imaging cameras only provide temperature information. They do not recognise flame per se.

Disadvantages of Thermal Imaging Cameras

The primary disadvantage of thermal imaging cameras for detecting fire is that they are more susceptible to false alarms than flame detectors, especially outdoors and in environments with other machinery, passing vehicles, and other benign hot items.

The reason for this is that they detect heat / temperature, not fire. Any source of heat that reaches the alarm thresholds may therefore raise an alarm. This can include things like hot machinery, hot vehicle engines and exhaust and other sources that may not actually be the kind of threat you wish to suppress. When an alarm is triggered by a benign source like this, it is called a “false alarm”, even though the system did exactly what it was supposed to do – raise an alarm due to a defined heat signature.

As a result, environments that regularly have heat sources that may trigger the thermal imaging camera system’s alarm—such as waste and recycling storage areas—may experience fairly frequent false alarms. This can present unwanted and potentially dangers suppression when not required, but may also cause operators to turn the system off to avoid such false alarms, rendering the autonomous fire suppression useless and exposing the facility to risk.

It is important to point out, however, that modern thermal imaging systems generally feature increasingly-sophisticated algorithms that reduce false alarms by ignoring things like moving heat signatures, such as those generated by a moving vehicle’s engine, etc. Also, they do allow known hot spots in their field of view to be ignored (or “masked”) so that they won’t cause an alarm.

Conclusions About Thermal Imaging Cameras

Thermal imaging cameras are a great option for early warning of high temperatures or a rapid heat buildup. False alarms may occur, particularly in areas where there are other heat sources, such as hot vehicles, hot lamps, etc. Care must be taken to mask known hot objects and to avoid false alarms that could result in possible danger from reaction by an autonomous robotic fire suppression system.

Video Analytics

How Video Analytics Works

Video analytics systems use advanced algorithms and computing to analyze regular visible video feed from a high definition video camera. This technology is used for many industries. In the fire detection industry, the video analysis is designed to detect, among other things, flames and smoke and sometimes reflections of flames.

Learn more about video analytics at: https://en.wikipedia.org/wiki/Video_content_analysis

Advantages of Video Analytics Systems

Video analytics systems can typically use any standard video camera feed. A frequently deployed option also allows the recording of the video feed they are analyzing, which can later be reviewed and analyzed after a fire event. They are also able to display the smoke and/or fire they detect on a video monitor for an operator so that she may respond appropriately.

Video analytics systems are also able to provide the coordinates of the fire and/or smoke. These coordinates can be used both by on-site crew to know where the problem is, but also can be used to autonomously aim the robotic nozzle of an autonomous robotic fire suppression system (ARFSS).

Disadvantages of Video Analytics Systems

Video analytics systems can be susceptible to false alarms, and they are typically slower to react than flame detectors or thermal imaging systems (≈10-20 seconds longer). They are not appropriate in all environments, such as where the sun, bright reflections or other flickering objects (such as tarps or flags flapping in the wind) are likely to trigger false alarms. Dust, steam and exhaust may also trigger a false alarm, as they can be difficult for these systems to distinguish from smoke.

As with thermal imaging camera systems, however, false alarms are reduced by “masking” (ignoring) known problematic objects, and also by means of ever-advancing algorithms that seek to ignore moving objects and other known sources of false alarms.

Conclusions about Video Analytics Systems

In the right environments, particularly in relatively static, indoor environments with little wind, dust and/or flashing objects, video analytics can be a very good technology for detecting smoke, fire and even reflections of fire. They can display this information for crew, provide alarms and warnings, and can also send the alarm and location data to an ARFSS. Careful consideration must be given to ensure that false alarms will be kept to a minimum.

Hybrid Thermal Imaging & Video Analytics Systems

How Hybrid Thermal Imaging & Video Analytics Systems Work

These detectors represent a relatively new and emerging class of fire detection technology.

Hybrid thermal imaging and video analytics systems combine both a thermal imaging system and a video camera with video analytics technology. Unifire calls this class of detectors Hybrid Thermal Imaging & Video Analytics.

The theory behind these systems is that they can provide three separate indicators of a fire: from the thermal imaging system, 1) a customized temperature pre-alarm and alarm; and, from the thermal imaging system, 2) the presence of a flame, and 3) the presence of smoke.

These three separate sources of data can be used by an autonomous robotic fire suppression system in any desired combination. For example, autonomous suppression may be programmed to commenced if, and only if, the detector detects: A) a flame detected by the video analytics, and B) a temperature at the same location with a temperature of over 100℃; and irrespective of whether the video analytics detected smoke. Any combination of the three channels can be used, and such logic would depend on the customer’s facility and conditions.

Advantages of Hybrid Thermal Imaging & Video Analytics Detectors

Hybrid thermal imaging and video analytics fire detectors are designed to provide fire detection that is less susceptible to false alarms than either of the respective technologies on its own. They seek to achieve this by allowing a conditional response, such as to trigger an alarm only if a certain temperature is measured AND the video analytics sees smoke and/or fire. In this way, the technologies act as a cross-check on each other, such as to ignore a hot temperature if no flame is visible to the video analytics, and vice versa.

Unifire believes that this technology may be intriguing and promising, and we are currently testing this technology for integration with the FlameRanger ARFSS. We do remain guarded, however, as to the actual susceptibility to false alarms in practice, as discussed in the disadvantages, below.

Disadvantages of Hybrid Thermal Imaging & Video Analytics Detectors

Not being a true flame detector, false alarms still remain a possibility. In theory, the risk of false alarms should be reduced as compared with either of the respective technologies on its own.

But, take for example, the fact that it is often the case that sources that are hot (and which would therefore raise a heat alarm from the thermal imaging part of the system) may also emit smoke, such as a moving vehicle and its exhaust. A system designed to detect heat and smoke may still trigger an alarm from a benign object, such as a moving vehicle. Moreover, dust may also possibly be recognized by the video analytics as smoke, so a hot spot, combined with dust in the air, may trigger a false alarm in some circumstances.

Conclusions About Hybrid Thermal Imaging & Video Analytics Detectors

For us, the jury remains out, as we ourselves have little data or experience from users of this technology in order to opine as to their efficacy or susceptibility to false alarms. The concept is certainly intriguing, and could provide a rapid and reliable means of detecting fire in the right circumstances, particular as this technology matures. In practice, however, it is too early for us to opine whether in fact these hybrid systems are a good choice. We are keen to test and explore this technology further and we are in the process of doing so.

Optic Linear Heat Detectors

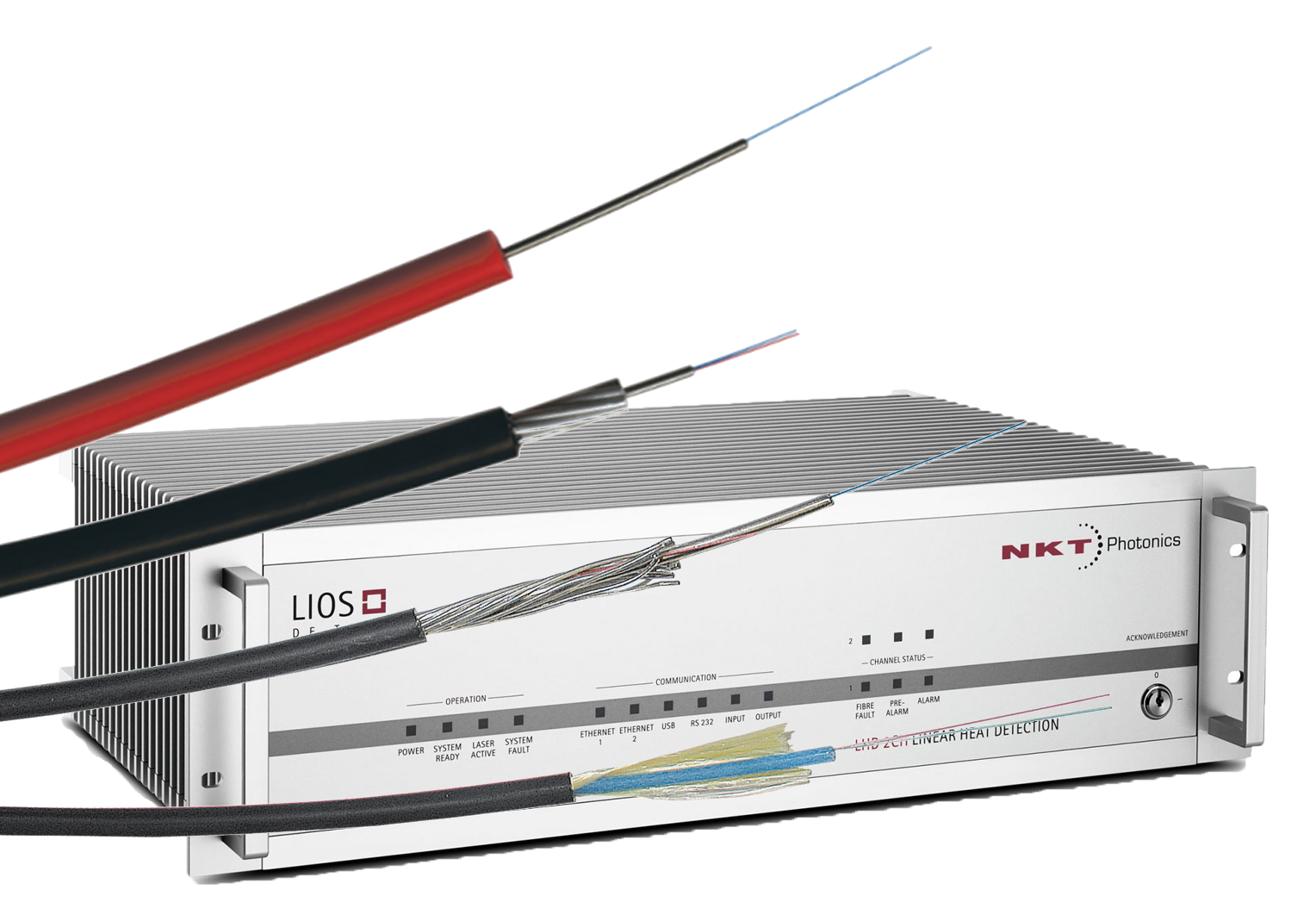

How Fiber-Optic Linear Heat Detectors Work

Fiber-optic linear heat detection systems pass light through a fiber-optic cable and, by using advanced computing technology that analyzes the light signals running through the cable, can reliably detect and locate heat buildups anywhere along the cable.

Learn more about Fibre optic Linear Head Detection (LHD) here: https://www.apsensing.com/technology/linear-heat-detection

Advantages of Fiber-Optic Linear Heat Detectors

Fiber-optic linear heat detection systems have a very low susceptibility to false alarms. They also can be very economical to install, particularly for large areas, because the fiber-optic cable itself is relatively inexpensive. These systems can provide continuous fire detection along the entire sensor cable length of up to 10 kilometers. They are also very low-maintenance and well suited for very harsh environments, including nuclear radiation. They are also immune to EMC and RFI, and are inherently safe in explosive environments.

Fiber-optic linear heat detection systems may in some environments be a good option for autonomous robotic fire suppression systems, particularly where it can provide sufficient response time and location information of the heat build-up, and where the other fire detection technologies discussed above are inappropriate or cannot provide advantages.

Disadvantages of Fiber-Optic Linear Heat Detectors

The primary disadvantage to fiber-optic linear heat detection is their relatively slow reaction time and relatively low accuracy of locating the fire. Before an alarm is triggered, heat must build up and heat the cable sufficiently to detect the fire. Moreover, the fire itself may be located near, but not exactly at, the location of the cable heat build-up, resulting in imprecise information as to the exact location of the fire. While this technology may be appropriate in some autonomous robotic fire suppression (ARFSS), generally the faster-acting technologies listed above are preferable.

Conclusions About Fiber-Optic Linear Heat Detectors

Fiber-optic linear heat detectors can be a cost-effective way to detect heat build-ups and fires, particularly over long distances. Of all of the technologies discussed in this article, however, they are by far the slowest to react and have a fairly imprecise (although perhaps sufficient) ability to locate the exact source of the fire. When it comes to successful fire fighting, including autonomous robotic fire suppression systems, reducing to an absolute minimum the time to detect and begin suppressing a fire is critically important. The faster you can put water on a fire, the better. For this reason, fiber-optic linear heat detection systems are the least attractive for most installation types, but could still be very useful in the right situation when the other detection technologies discussed above are impracticable.